PEM Motion GmbH will kick-off a consortium project in cooperation with the Chair for Production Engineering of E-Mobility Components (PEM) and the Institute and Chair of Metallurgical Process Technology and Metal Recycling (IME) at RWTH Aachen University.

Project Electrical Vehicle Battery

The project with the topic „EV Battery – Yesterday’s Scrap is Tomorrow’s Gold“ will start this month. The first project meeting, in which partners will get to know each other and discuss the exact focus of the project is going to be in Aachen on March 19, 2020. Current batteries and battery systems are only designed for the first phase of their life. The aging process of batteries and the State of Health (SOH) after their first use is currently unknown and varies between different batteries and cell types. Re-use and recycling of batteries imply high tear down costs and efforts at the moment. There is no prevailing battery concept which focuses on sustainability and second use both in terms of the product and the process.

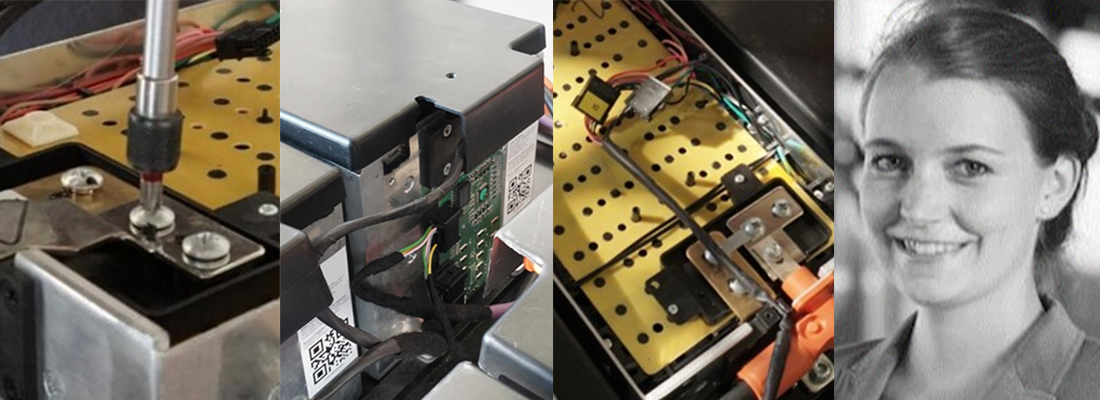

The approach of PEM Motion GmbH is to form a consortium of renowned companies from the automotive industry to formulate study hypotheses. Eight participants, including two OEM’s, one Tier-1 supplier and partners along the battery value chain are going to participate in the consortium project. In the project various EV battery packs from different manufacturers and different types of cell designs will be disassembled and tested regarding their state of health, aging behavior and other important parameters to specifically evaluate the condition of the battery from pack to cell level. Components will be analysed and assessed and a detailed overview of industry benchmarks and a best-practice of various aspects of battery components and their suitability for recycling will be provided to the consortium. All participants benefit from a profound economic and technological evaluation and overview of the state of the art of batteries and battery systems on the market.

Battery engineering

Participating companies have the possibility to design and influence the content of the study to acquire specific knowledge according to their needs. They get an overview of industry standards and state of the art battery and battery system concepts as well as an assessment of innovations suitable for Re-X (Re-use/ Re-manufacturing/ Re-cycling). Through different industries of consortium participants along the value chain, all partners have the possibility to exchange their expertise and profit from the understanding about upcoming needs and developments in the field of battery engineering. We expect to gain a number of novel insights which are pioneering in this field and are glad that we have found partners, who are also convinced of the importance of including decisions on second life applications into the design and structure of batteries. This is a first and necessary step towards a more efficient use of resources.

If you are interested in a similar benchmark outside the scope of this study, please contact PEM Motion GmbH.

About the author

Sarah Fluchs

Director Remanufacturing & Sustainability at PEM Motion GmbH

Related content

Reverse logistics: a prerequisite for remanufacturing electric vehicle batteries

Electric Vehicle Challenges & Opportunities for European Remanufacturers

Steady growth for worldwide battery electric electric vehicle fleet