Recruiting skilled reman workers is a big problem. Volker Schittenhelm looks at a German scheme which could provide a model for the industry if it is transferred to other national FIRM members.

This is an exciting time for the industry: remanufacturing-related issues such as design4reman, the circular economy, electronic reman, CO2 footprint reduction, environmental life cycle assessments have all found their way into the academic arena, creating interest at universities and research institutes.

This is more than positive because it leads students, engineers and young people to think about environmental protection. And it also leads to remanufacturing being recognised as the ultimate form of environmental protection - versus recycling, waste management and waste avoidance.

Skilled recruitment

This is where the problem starts. There is no educational institute, school or training centre in Europe from which engine reman garages can recruit skilled engine reman staff. Students at school or in technical training – even if they are interested – have no chance to get educated and trained for engine remanufacturing.

The only solution to solve that problem – at least for Germany - was to take the reins and establish an own educational project. So the VMI, the German association of engine remanufacturers, established a two-years engine reman education and training programme (ETP), backed by their sustaining members from the engine component and reman industry.

Pilot module

It includes basic engine knowledge, everything on engine components including materials, component and engine failure diagnosis, measuring techniques, quality, documentation, cleaning issues and component reman practical trainings.

To make it round legal issues like branding, warranty, guarantee, general terms and conditions, cross-border business as well as strategical and business development – related issues are integrated part of the ETP. Thus, the VMI offers a wide range of content, where newcomers from school, career changers, administration staff, but also basic skilled employees, taking – over additional responsibilities in the garage or company, can be well educated.

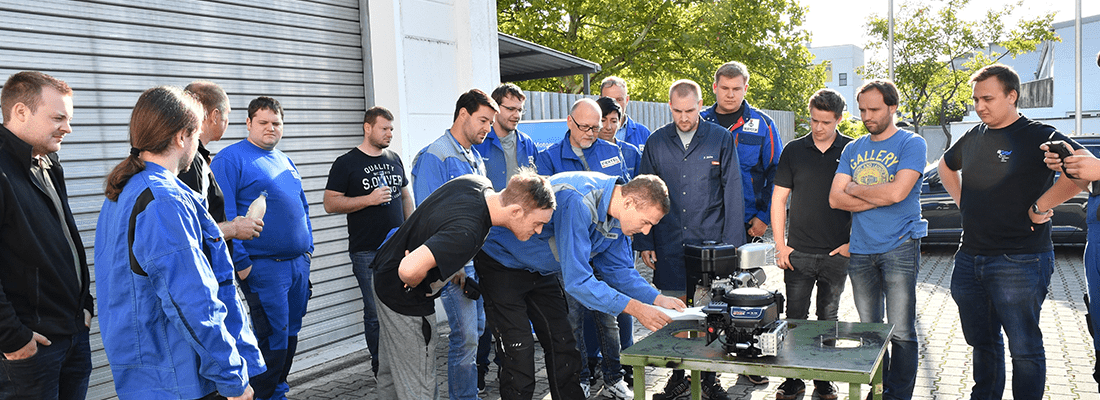

At the end of September this year, during Automechanika, the VMI started the first pilot module. Hosted by Briggs & Stratton in Germany, a three-day knowledge transfer by experienced speakers from the engine and engine reman industry, practical demonstrations and engine failure diagnosis based on intentionally crashed engines led to a very successful launch.

Save the dates

• Module 2 will take place at the end of January, hosted by MS Motor Service International, worldwide active engine parts service organisation of Kolbenschmidt-Pierbung in cooperation with one of the leading gasket technology manufacturers, Elringklinger.

• Module 3 is scheduled for mid-April and hosted by Motair Turbolader, one of the main German remanufacturers of turbochargers.

• Modules 4-9 will follow regularly in three-month steps, so that the final examination module is scheduled for the second quarter of 2020. Round 2 – the subsequent ETP cycle – is planned to start in October next year.

So, if you are a German engine remanufacturer, and you need engine reman education and training, join VMI and profit from its activities. For general information about modules, content, time frame and certification of engine reman training and education get also in contact with VMI (www.vmi-ev.de) or email FIRM at communication@firm-org.eu.

Conclusion

This is a German solution, but it could be transferred to other national FIRM members. And if FIRM – in this transfer process - can match all the national education programs to a unique European one, I am sure that our engine reman industry will no longer have any problems in recruiting skilled people.