As well as being a massive OEM, Caterpillar has the largest reman operation in the world – but Tana Utley tells Adam Hill there is synergy, not tension, between the new and reman businesses.

Caterpillar’s bold yellow logo is highly distinctive and known wherever there is demand for heavy-duty construction and mining equipment – which is to say, pretty much anywhere in the world. It is a massive operation: the company brought in revenues of more than $47 billion in 2015. What is perhaps less well known is that Caterpillar is also the largest remanufacturing organisation in the world. That is not an idle boast: Tana Utley, who has responsibility for Caterpillar's remanufacturing business, cites a US International Trade Commission survey which supports the claim. “We have great breadth and depth,” she tells ReMaTecNews. “We have a large customer base around the world and a large dealer base connected to it. There is a considerable sustainability impact: over 500,000 tons of material has been returned to us and repurposed since 2010.” In a fragmented industry which is largely made up of small to medium-size companies, Caterpillar is therefore an anomaly in remanufacturing. Cat Reman employs 4,000 people and has facilities in the US, South America, Europe and Asia. “It is a sizeable business within Caterpillar,” Utley points out. “We’re part of a big company and we use that to our advantage.” Yet it remains relatively intimate too, she says: “I’ve never been to one of our facilities, anywhere in the world, where I didn’t run into somebody I already know.” Reman has a vital place in Caterpillar’s operation, she believes. “Reman is the best way to provide the lowest lifecycle operating cost to our customers. Cat equipment is designed so durably, and is designed up front for multiple rebuild cycles. If we can breathe new life into the equipment then we can help the customer.” The Cat design philosophy is, of course, considerably helped by access to its own intellectual property (IP) across the manufacturing and remanufacturing continuum. “Access to IP is the greatest competitive advantage,” she admits. “This is very tightly embedded.” Designing for reman up front means that everyone has access to designs throughout the process – the sort of access that third-party reman companies can only dream of. “I would hope we are viewed as large and connected to our customers through our dealer organisation,” she continues. “The dealer organisation is so critical in getting the cores back to us, and this is something ingrained with our business.” Reverse logistics is vital: accounting systems mean that dealers are credited for core return and Caterpillar’s slick marketing machine means that none of them can be in any doubt about the ‘lowest lifecycle operating cost’ message. “Dealers understand the value proposition for customers,” she insists. “Our machines run thousands of hours per year and parts consumption and parts costs count in the equation for the customer. That also gives dealers the opportunity to earn income by delivering product support services to the customers.” None of this would work unless there was a significant degree of cooperation internally, Utley suggests.

Important collaboration

“Caterpillar is a great big company with a lot of different manufacturing sites around the world. There is a lot of collaboration with our brothers and sisters - for example on lean manufacturing, purchasing, product design and safety – across organisational boundaries. We also spend a fair amount of time in the field with our dealers and customers.” This is particularly important in the case of customers, “looking at ways we can use remanufacturing to help them make more money out of the Cat equipment he uses”. Complacency is the enemy of successful business, and Caterpillar carries out regular horizon scanning. “We are looking to continuously improve ideas,” Utley says. “We see what’s out there in the marketplace. A lot of companies are keen competitors on cost – and that keeps us keenly focused when it comes to the cost of reman. In addition to extensive technology development within Caterpillar, we also have partnerships with universities, working with them to develop salvage techniques.” This is one of the most notable things to look out for in future, Utley believes. “Our continuing research into increasing salvage” takes the form of looking at ways in which incoming cores can be better assessed and used. “The fact that we can go back to the print gives us an edge,” she reiterates. “We are always trying to ensure quality.” Another important area is at the higher technology level, looking at more forms of metal deposition, “how we can resurface things, give them a new performance”. Advanced remanufacturing processes such as additive manufacturing are an area of research for Caterpillar. Another area the company is exploring is how to best use big data. The sheer volume and quality of consumer information which is increasingly available to companies is helping to change the way they do business, and Cat Reman is also starting to scratch the surface of the Big Data revolution. “We’re beginning to use data in a new way, giving us a much better understanding of how customers use their equipment.” She is confident about the future. “Reman will grow with Caterpillar and our customers: if you want to know where reman is going, look at the field population. The overriding thing about growth is that it is pulled by our customers.

Asia potential

Reman in Asia has potential to be larger than in the developed economies – but we’re focused on how to reduce the lifecycle cost wherever the customer is. Look at our portfolio – engines, components, hydraulics, drivetrain - that is the lens through which we view the world.” That portfolio is set to expand – and in much the same way, Caterpillar’s interest in best practice extends well past its dealer network onto a wider stage: the company is represented on the Remanufacturing Industries Council, for instance. “It is important that we get the reman message out there,” Utley says. “We would like to make it more successful.” Awareness raising, regulatory efforts and the development of industry standards are all important parts of this, she thinks. Given the group’s global reach, the message stretches well beyond the borders of the US too. “We try to help foreign governments understand that reman is like new, and that – particularly in Latin America and Asia – it will help them.” Business does not happen in isolation, of course, and some outside influences are more significant than others. On that subject, it has not escaped the company’s attention that the political landscape in the US – and therefore the world – has changed substantially in recent times.

Working with Trump

Asked about the election of Donald Trump to the US presidency, Utley insists that Caterpillar will be “fully prepared” to work with him and welcomes the new president’s positive comments on putting money into infrastructure investment and his pledge to restructure the US taxation system. Whatever happens in the macroeconomic environment, including reman in product design gives Caterpillar a major advantage in the marketplace – and it is not one the group looks keen to relinquish anytime soon. Yet one of the major stumbling blocks to the uptake of reman products by consumers is achieving acceptance. How does Caterpillar go about ensuring that customers know how good reman can be? “We share the numbers with them, quite frankly!” Utley laughs. The cost of new versus reman can clearly be quite persuasive. “But each customer has unique needs,” she continues. “It might make sense for some customers to buy new.” From the sound of it, this could lead to tension at times between Caterpillar’s new and reman operations. “I’d call it synergy,” says Utley easily. “The company realises reman can improve the profitability of the customer and Caterpillar.” After all, if you have significant scale in your operation, it makes sense to use it. “We don’t want to lose the sale – we’re driven to meet the customer’s needs. If they want a new component then we accept that,” she concludes. “I just want it to be a Cat component!”

Cat Reman

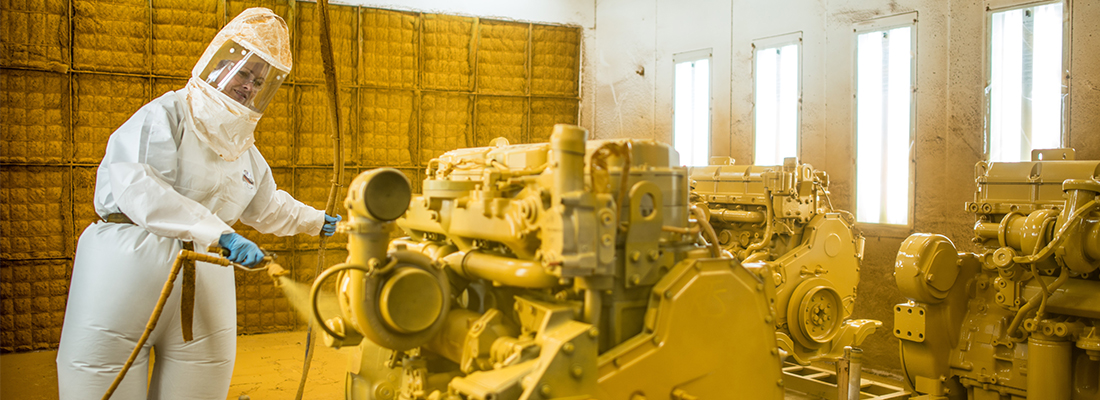

Cat Reman has 4,000 employees in North America, South America, Europe and Asia-Pacific. Its portfolio includes 7,000 reman products including engine parts and components, turbines, gas compressors, locomotives, railcars, hydraulics and drivetrains. As components are designed for remanufacture, there was a 93% end-of-life take-

back in 2015. Caterpillar says that 500,000 tons of end-of-service-life material returned to productive use since 2010. As an ex change business, the company charges a deposit for its reman products – when the customer returns their used components, Caterpillar refunds their deposit. The proprietary core management system globally manages core returns from dealers and Caterpillar inspection facilities and determines the core credit amounts that will be refunded.