Remanufacturers are Atlanta-bound and will be joining with NACE Automechanika to show off new products, to network – and to meet new customers. ReMaTecNews US correspondent Denise Rondini talks to some Big R Show exhibitors.

Atlanta, Georgia is the place to be from August 8-10 as the Automotive Parts Remanufacturers Association (APRA) hosts its annual US convention: The Big R Show. Having moved from Las Vegas, this year Big R is co-locating with NACE Automechanika, billed as the US’s leading international trade fair for the automotive service and collision repair industry.

The event held at the Georgia World Congress will feature 3,400m2 of exhibition space housing more than 350 exhibiting firms in eight product groups:

- parts and components

- electronics and systems

- accessories and customising

- repair and maintenance

- dealer and workshop management

- car wash, car and recondition

- alternative drive systems and digital solutions

- tyres

Attendance is expected to top 7,700. Joe Kripli, president of APRA, says the association chose to co-locate with NACE Automechanika for a variety of reasons - including the audience it attracts. “Our exhibitors want to see installers, repair shops and manufacturers; at this show they will get a good cross-mix,” he says. “With the collision people in attendance this gives us a whole other avenue we have never been in front of before. If a car is wrecked the collision repair people may have to put on new calipers, rotors, water pumps, a reman engine, what have you. I am looking forward to that opportunity for our members.”

New customers

Exhibitors agree that meeting potential new customers is a primary reason for attending the show. Elisa Carlini, marketing and communications co-ordinator for Italian firm Gobbi Spare Parts, says the company is attending the show “because it is an excellent showcase in the world of the spare parts market”. She adds that it gives the company “the possibility of interacting with local businesses”.

Tony Pavesich, surface finishing industry leader at Houghton International in Chicago, adds: “We are exhibiting to showcase our technology and to meet potential new customers in the industry.” Houghton specialises in remanufacturing chemicals, including cleaners, paint strippers, rust and oxide removers, metal working fluids and complete processes. He hopes to come away from the show “with an increased awareness of the needs of the industry as well as new contacts that have a need for our experience and expertise in this area”.

ARMEX is a global leading brand of sodium bicarbonate abrasive material media located in New Jersey. While business manager Brian Waple says reman is one of the company’s key markets, it is also using the show as an opportunity to launch a new product for the first time in over a decade. Re-Man XL is a blasting abrasive specifically formulated for the transportation, remanufacturing and rebuilding industry. Complete details about the product will be available at the show.

New products

Houghton will also be introducing a new line for cleaning and stripping paint from aluminum components. Tec Strip 6 Plus provides faster and more efficient cleaning and paint removal than anything previously on the market, according to Pavesich.

Meanwhile, Ashburn Chemical Technologies, from Houston in Texas, will also be debuting a new product. EnviroGreen SuperSonic is an ultrasonic cleaning solution. Ken Wollin, vice present of marketing, says: “In ongoing tests, this product has proven to outperform traditional ultrasonic cleaners in cleaning speed and total particle removal.”

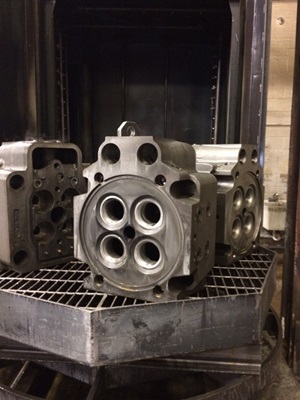

The company has expertise in manufacturing chemical solutions specifically formulated for remanufacturing applications. “We have recently developed new technologies that surpass current formulations for cleaning, degreasing and removing carbon deposits from core components including engines, transmissions and related parts,” Wollin adds.

Ashburn is exhibiting at the Big R show in order to meet with reman professionals looking for ways to improve productivity in their cleaning processes, increase chemical bath life, reduce waste disposal and reduce overall operating costs, he explains.

New ideas

In addition to exhibits at Big R, there will also be seminars and speakers. All activities at the event are open to APRA members including workshops and educational sessions. Kripli says APRA decided to piggyback on Automechanika’s programme. “There are technical seminars on things such as electronics and turbochargers and fault code diagnostics and transmissions,” he says. “There is just such an array of subjects. There are even sessions on HR [human resources] and IT. This is beneficial to our members.”

Houghton’s Pavesich says he is excited about the move to Atlanta: “Hopefully it allows more attendees from the eastern US.” Waple says the show’s location does not matter to him, but he is “happy that the show is now part of Automechanika”. In fact, he says: “If the Big R did not join Automechanika, we would not have attended the Big R show this year.”

On the other hand, Wollin has some concerns about the attendance at this year’s show. “This is our first time exhibiting, so we hope the attendance is as good or better at this new location.”

Kripli adds that further out APRA is looking to host its convention in different cities. “We have to determine - is Nashville a good place? Is San Diego? We definitely want to move around and cover the Midwest, Southeast, West Coast to give people more opportunity because there are a number of people who just don't want to travel far - or who can’t.”

Cleaning up in Atlanta

Several manufacturers of cleaning products will be introducing new products at this year’s Big R Show. ReMaTec News chatted with them about the latest trends and developments in cleaning products and cleaning technologies.

Ken Wollin, vice president of Ashburn Chemicals, says: “Although not new, there has been an increase in the use of ultrasonic cleaning processes in reman cleaning operations.” He adds that the company has developed a new water-based ultrasonic cleaner-degreaser to meet the needs of the reman industry.

Brian Waple, business manager at ARMEX, cited green products and non-destructive cleaning as two trends he is seeing when it comes to cleaning products and cleaning methods.

According to Tony Pavesich, surface finishing industry leader at Houghton International: “The biggest trend is [hazardous air pollutants] HAPs-free paint stripper technology that allows the end user to increase production throughput while ensuring that they remain environmentally compliant with all new regulations.”